Test Sled Fleed

Mobile Barrier Vehicle Substitute System High Speed -/ Deceleration Test Sled 4-t Sled Pole Sled CS300

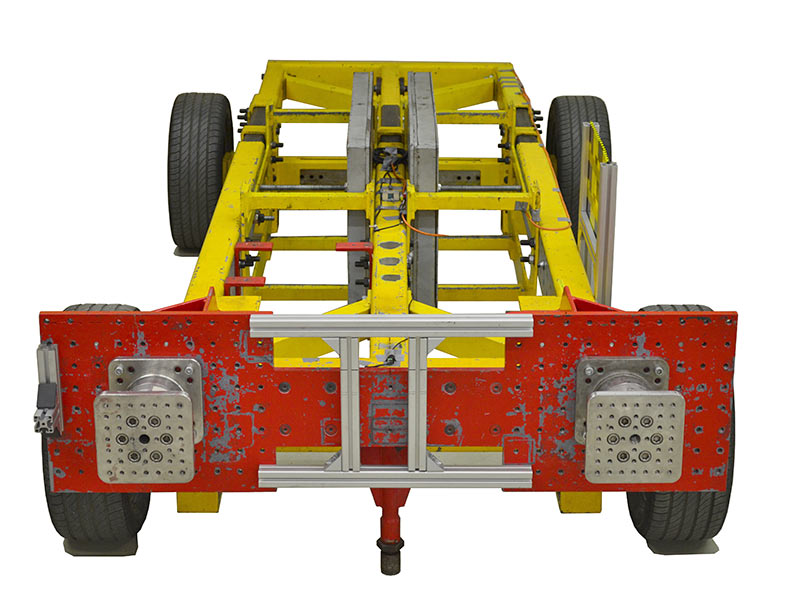

Mobile Barrier

Applications

- Usable as mobile barrier (MB) or as mobile deformed barrier (MDB)

- sled tests with bumper systems

- Sled for RCAR Structure rear tests (AZT rear tests)

- Side Impact according to: EuroNCAP Side Impact / IIHS Side Impact / ECE-R95

- Rear Impact according to: FMVSS 301

Technical Data

- Hydraulic brake system at all four wheels/ Activated per radio or automatically

- Extra weight above the axes to idealise the weight distribution

- Individually settings of centre of gravity

- Flexible settings of different deformation elements and impactors

- Flexible carrier system for camera and data aquisition

- Digital model to simulate crash tests and to validate simulations

- Length: 3400 mm (without deformation element)

Width: 1726 mm

Height: 825 mm (without camera/data aquisition) - Shield: 650 mm x 1700 mm [30 mm aluminium plate]

- Frame width: 1060 mm

Frame height: 530 mm - Track: 1500 mm (185/65 R15, ET35, 6Jx15H)

Wheelbase: 2500 mm - Weight: 745 kg – 3100 kg (Ballast plates)

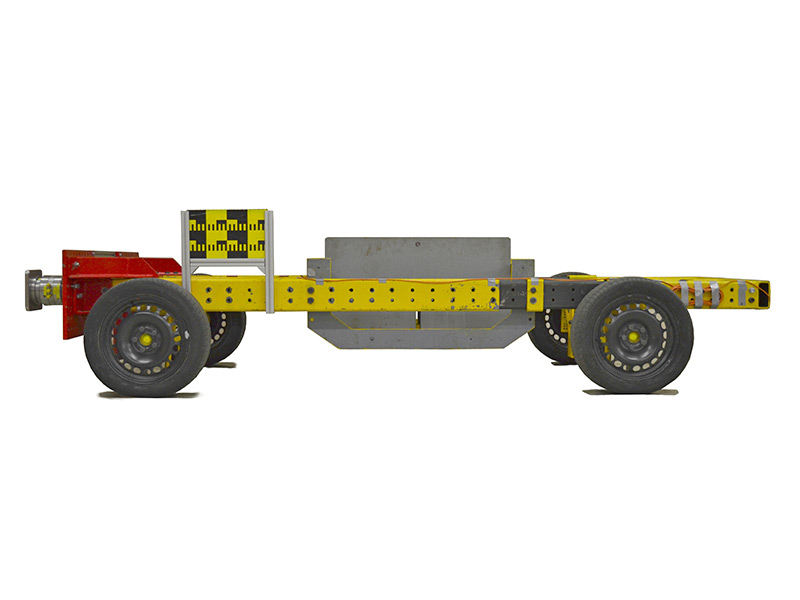

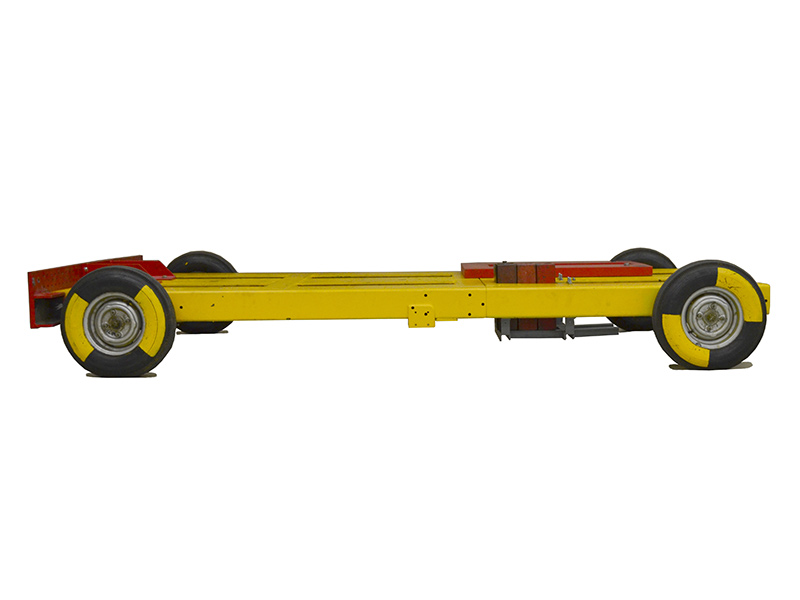

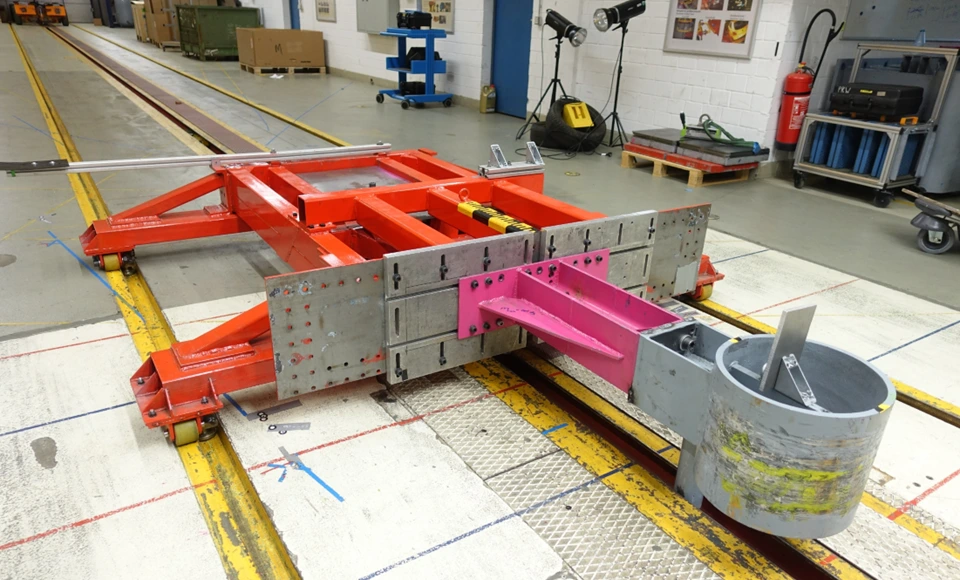

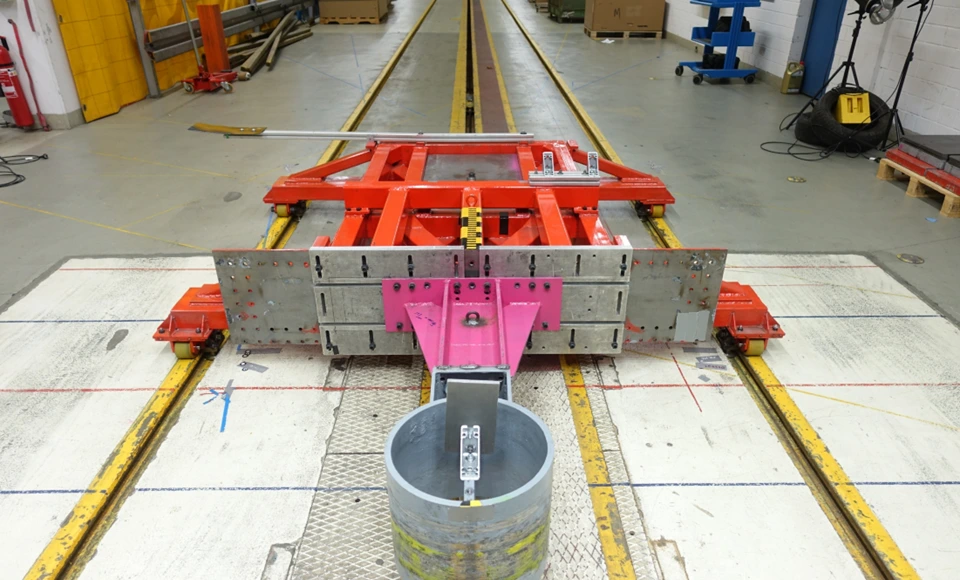

Vehicle Substitute System

and 3 more pictures

Applications

- Sled tests with bumper systems

- RCAR Structure/Bumper front/rear

Technical Data

- Measurement of the forces in the longitudinal beam behind the crashboxes (3-axial), even with four load paths

- Variable adjustable track width, wheelbase, centre of gravity, mass moment of inertia and overhang

- Flexible settings of different deformation elements and impactors

- Digital model to simulate crash tests and to validate simulations

- Length : 2070 mm – 4140 mm (variable, without load cells)

Width : 1540 mm (total)

Height : 685 mm (without extra weight) - Shield : 420 mm x 1500 mm

- Frame width : 1000 mm

- Track : 1300 mm – 1730 mm (Wheel 195/50 R15, ET34, 5,5Jx15JH2)

Wheelbase : 1600 mm – 3700 mm (variable) - Weight : 730 kg – 3200 kg (variable)

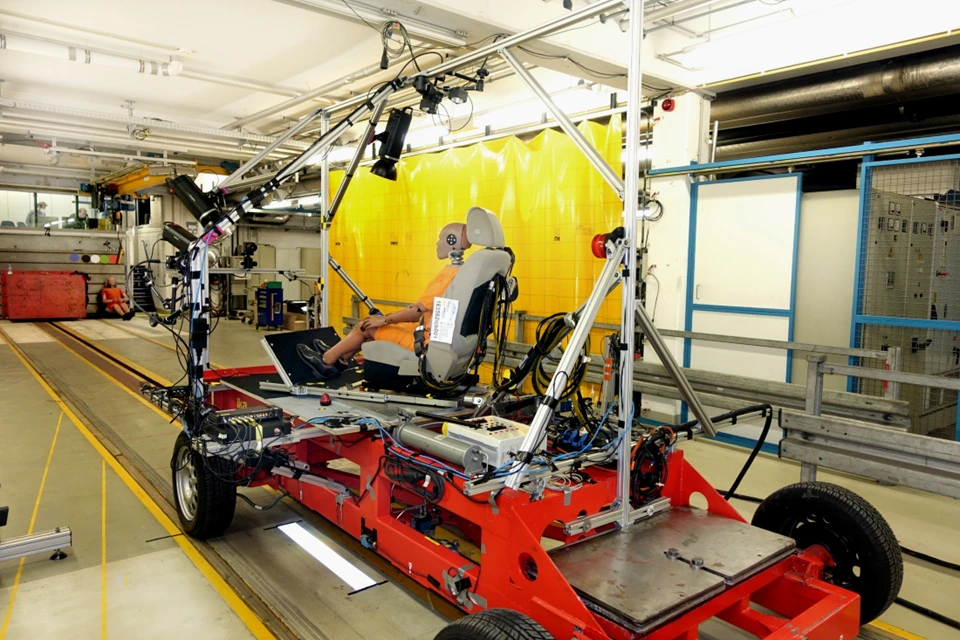

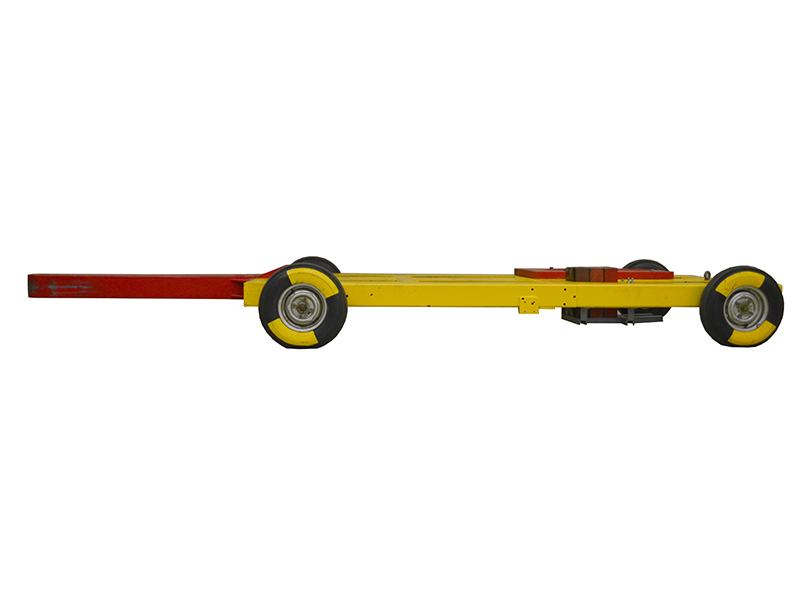

High Speed -/ Deceleration Test Sled

and 4 more pictures

Applications

- High speed sled tests

- Either crash tests at samples or deceleration tests with help of a deceleration device

- Tests according to ECE-R 17

Technical Data

- Flexible sample application

- Two different lengths/wheelbases

- For choice: vehicle wheels or heavy-duty caster

- Digital model to simulate crash tests and to validate simulations

- Length: 2010 mm (short) or 3300 mm (long) (without prong)

Width: 1800 mm (total)

Height: 510 mm (without extra weight / wheel diameter)

Prongs length: 1500 mm - Frame width: 1450 mm

- Track: 1670 mm (front) / 1610 mm (rear)

Wheelbase : 1375 mm (short) or 2670 mm (long) - Weight : ca. 450 kg (short) / 725 kg (long) (gross weight) up to 3000 kg (with heavy-duty casters)

Deceleration device mandrel weight: 155 kg

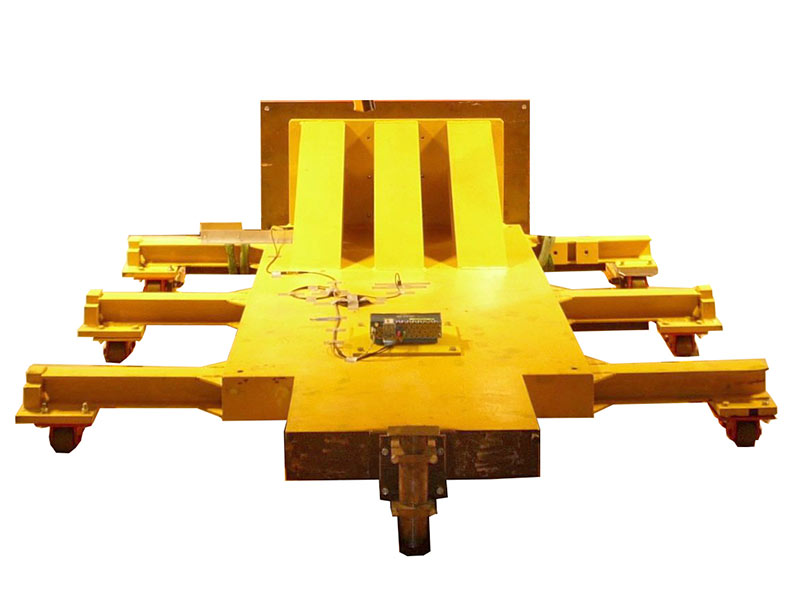

4-t Sleds

Applications

- Sled tests with train crashbox

Technical Data

- Digital model to simulate crash tests and to validate simulations

- Length: 3000 mm

Width: 2400 mm

Height: 800 mm - Frame width: 1150 mm

- Track: 2150 mm

- Weight: approx. 4000 kg

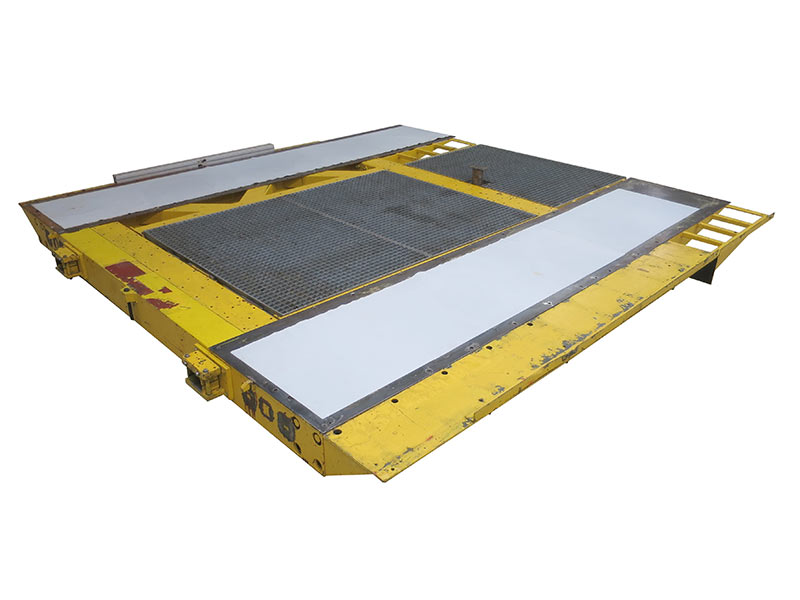

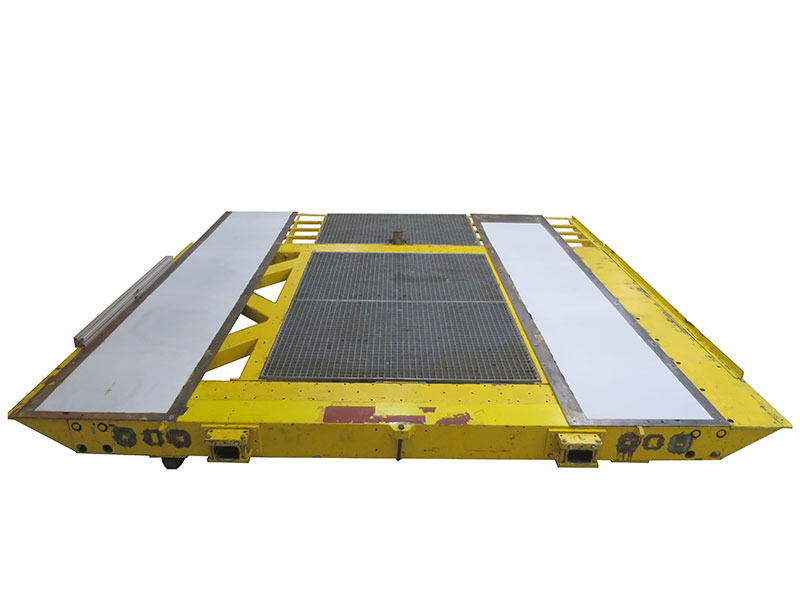

Pole Sled

Applications

- Pole impact according to EuroNCAP/ANCAP, GTR 14, UN R135

- Misuse Tests (Curb impact)

Technical Data

- Coated with Teflon (to minimize friction) or with friction linings

- Deceleration with deformation elements (thin-wall tubes)

- Length: 3700 mm

Width: 3605 mm

Height: 300 mm - heavy-duty casters

- Track: 2300 mm

Wheelbase: 2300 mm - Weight: 2036 kg

- Wheelbase of test vehicle: 1500 mm up to 3400 mm (90º impact angle)

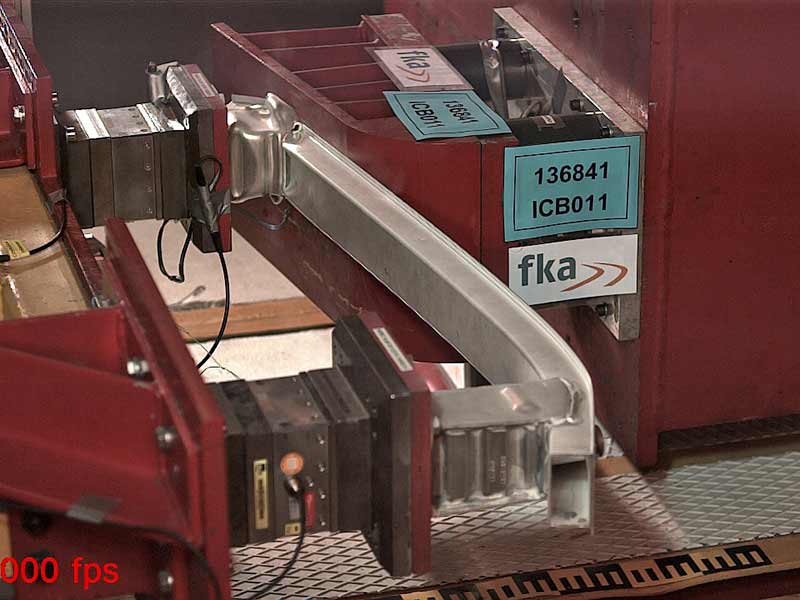

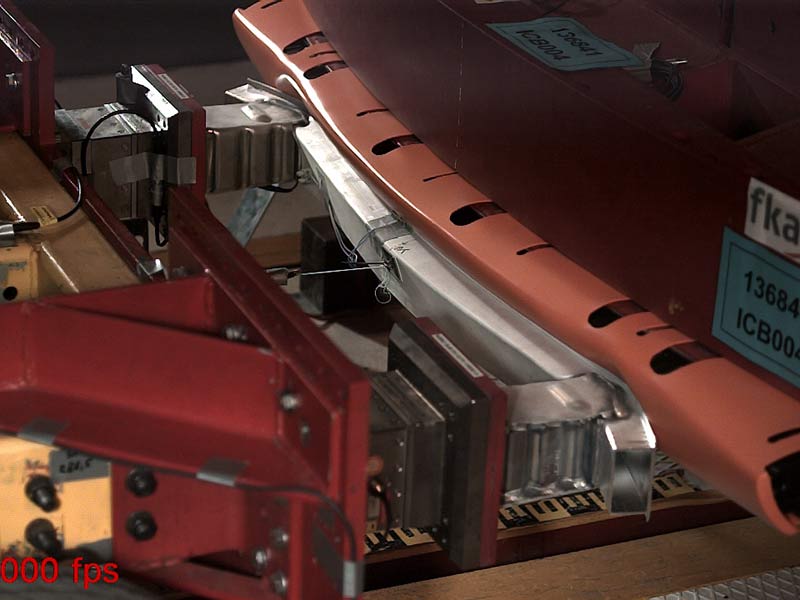

CS300

and 1 more picture

Applications

- Conducting of high speed crash tests with crash management systems

- Extension/upgrade of drop tower in terms of impact energy/velocity or impactor area/size

Technical Data

- Weight min: 380 kg

- Weight max: 1500 kg

- heavy-duty caster with locking to track (prevention of degrees of freedom in y- and z-direction)

- Flexible settings of different impactors

Contact

Thomas Lennartz M.Sc.

Head of Vehicle Concepts & HMI

+49 241 80-25687

Email

Service

Cooperations

Address

Institute for Automotive Engineering

RWTH Aachen University

Steinbachstraße 7

52074 Aachen · Germany

![[Logo: Institute for Automotive Engineering (ika)]](https://ika.rwth-aachen.de/images/ika-logo-a-blau-blau-rgb.svg)